Service kit KIT RBC90/K1+K2

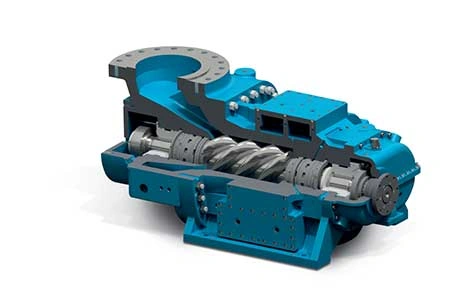

KIT RBC90/K1+K2 air inlet valve service kit is an important part in screw compressors. It is used to control and prevent the entry of foreign particles and pollution into the compressor. In these types of compressors, air enters the compressor through the inlet valve, where it is compressed and exits from the outlet.

- Portable

- Oil Flooded

Service kit KIT RBC90/K1+K2

KIT RBC90/K1+K2 service kit is actually an air inlet valve for screw compressors. This part is used to control and prevent the entry of foreign particles and pollution into the compressor.

The air inlet valve is an important part of screw compressors. Its main function is to protect the compressor from foreign particles such as dust, moisture, oils and other contaminants. By preventing harmful particles from entering the compressor, this air valve prevents damage and shortens its useful life. Also, by controlling the entry of clean and dry air, the possibility of better performance and more efficiency of the compressor is provided.However, for more detailed information about KIT RBC90/K1+K2 service kit and how to install and use it on screw compressors, it is recommended to visit the support office of the manufacturer or dealer and get the relevant details from them.

The main task of the KIT RBC90/K1+K2 service kit The main task of the KIT RBC90/K1+K2 service kit is to prevent the entry of contaminated and unwanted particles into the compressor. Particles such as dust, dirt, moisture and airborne substances can enter the compressor and cause damage and shorten the life of the compressor. Therefore, using the air intake valve as an effective filter can help the intake air to be clean and free of harmful particles.

RBC90 is one of the compressor unloader series, RBC head. The RBC series itself has two types: RBC160, RBC90. Currently, we are reviewing the RBC900 model. Inlet air flow rate in fully open mode (m3/1): 20, outer diameter of inlet valve (mm): 100, inner diameter of inlet valve (mm): 90, working pressure (bar): 16 bar, electric valve voltage (V) : 24V - 220V Weight (Kg): 7/5 Unloader installation The installation of unloaders is similar to each other. The unloader is installed on the inlet flange of the air conditioning unit directly or by means of a conversion flange. After that, the sockets of electric valves are connected to it.

Technical Specifications

| Location | Type | Motor/Engine Power | Flow | Pressure |

|---|---|---|---|---|

| Portable | Oil Flooded | 51 - 100 (38 - 75) | 276 - 575 (7.80 - 16.30) | 150 - 225 (10 - 16) |