Centrifugal compressor

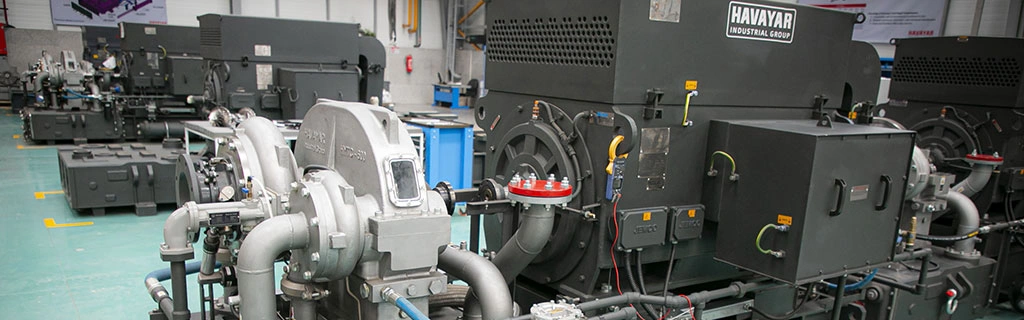

A wide range of Centrifugal Compressor (Centrifugal Compressor) is provided based on API 617. With a high degree of reliability and low maintenance costs, these compressors are used in the petrochemical and refinery industries, natural gas, steel and cement plants, food industries, and transportation.

- Stationary

- Oil Flooded

-

intake pressure: 17 bar

-

discharge pressure: 45 bar

Centrifugal compressor

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua Egestas purus viverra accumsan in nisl nisi Arcu cursus vitae congue Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua Egestas purus viverra accumsan in nisl nisi Arcu cursus vitae congue Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua Egestas purus viverra accumsan in nisl nisi Arcu cursus vitae congue Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua Egestas purus viverra accumsan in nisl nisi Arcu cursus vitae congue Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua Egestas purus viverra accumsan in nisl nisi Arcu cursus vitae congue Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua Egestas purus viverra accumsan in nisl nisi Arcu cursus vitae congue

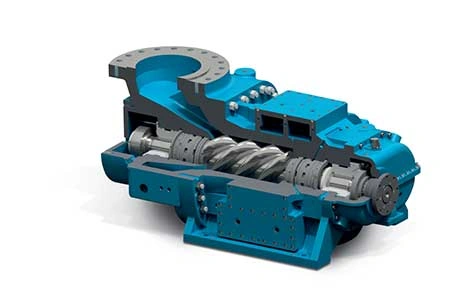

The issue of pressure increase is very important in various industrial processes. Centrifugal compressors are a type of dynamic compressors capable of creating medium pressure and high flow rates, and the principles governing the design and construction of each of its parts are based on API 617 and API 672 standards (for more information, see (What is the API672 standard and what is its use?)Air is sucked into the first stage chamber through the suction opening equipped with a filtration system and with the adjustment of the inlet flow by the inlet control valve (IGV: INLET GUIDE VANE) and pushed towards its center using the impeller blades and pushed by the forces Centrifugal is thrown out towards the periphery of the impeller.

In fact, by using centrifugal force, the amount of fluid pressure increases while passing through the impeller.The impeller is mainly made of stainless alloy steels and can be of open or closed design. Open design is more common in air applications. After each impeller (IMPELLER), the speed of the air increases dramatically and then the fluid enters the diffuser (DIFFUSER) and as the speed of the fluid decreases, its static pressure increases. In other words, in this process, the kinetic energy of gas at low pressure and high speed is converted into low speed and high pressure.

Technical Specifications

| Location | Type | Motor/Engine Power | Flow | Pressure |

|---|---|---|---|---|

| Stationary | Oil Flooded | up to 50 (up to 37) | 276 - 575 (7.80 - 16.30) | up to 125 (up to 9) |