Nitrogen compressor

The nitrogen generator is one of the products of Baron company, which is sold at various prices. In general, nitrogen gas is used in various industries, from food packaging to mining. All these industries need nitrogen gas continuously.

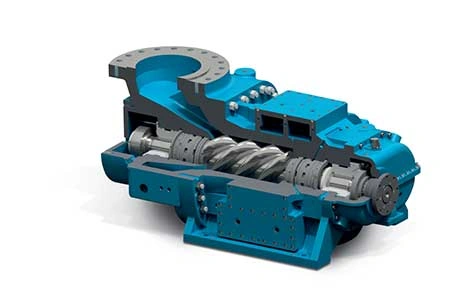

- Stationary

- Oil Flooded

-

intake pressure: 15 bar

-

various CNG fueling stations

Nitrogen compressor

The answer to this question is the same as the previous question. The nitrogen generator produces the required nitrogen in a set of other devices and equipment. There are two ways to produce nitrogen with a nitrogen generator. In the first method, PSA nitrogenizer is used. In this method, nitrogen in the air is separated during the absorption process. In the second method, nitrogen is produced by membrane separation.In the membrane process, air enters through hollow fibers (holofiber polymer membranes) that act like reverse filters. Oxygen, carbon dioxide and water are present in the air in small amounts, so they penetrate through the fibers. In contrast, nitrogen molecules are larger. That's why they are the only thing left. What is the PSA technology in the nitrogen generator?

Many companies use nitrogen cylinders to get the nitrogen gas they need. But nitrogen cylinders need a lot of money. The nitrogen generator can help industries to access the source of nitrogen gas at the place they need at a lower cost.

What does a nitrogen generator do?

The answer to this question is the same as the previous question. The nitrogen generator produces the required nitrogen in a set of other devices and equipment. There are two ways to produce nitrogen with a nitrogen generator. In the first method, PSA nitrogenizer is used. In this method, nitrogen in the air is separated during the absorption process. In the second method, nitrogen is produced by membrane separation.In the membrane process, air enters through hollow fibers (holofiber polymer membranes) that act like reverse filters. Oxygen, carbon dioxide and water are present in the air in small amounts, so they penetrate through the fibers. In contrast, nitrogen molecules are larger. That's why they are the only thing left.

What is the PSA technology in the nitrogen generator?

PSA technology is a special nitrogen production technology that separates nitrogen molecules from oxygen molecules in the air. This technology uses carbon molecular cylinders or CMS.Nitrogen separation is done in such a way that cylinders absorb oxygen and nitrogen gas is released as a product. Oxygen gases, carbon dioxide and other gases that are process waste gases are discharged.

Technical Specifications

| Location | Type | Motor/Engine Power | Flow | Pressure |

|---|---|---|---|---|

| Stationary | Oil Flooded | 51 - 100 (38 - 75) | up to 275 (up to 7.80) | up to 125 (up to 9) |