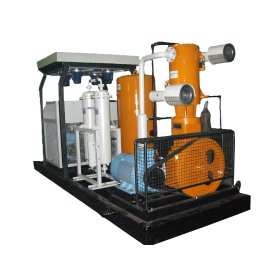

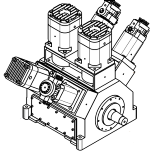

Baron compressor types

IIW-type is the high-end design of Baron used for creating extreme pressures as well as pressurizing gases in which high discharge temperatures are not desirable.

Read More

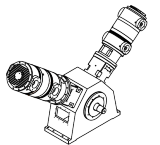

VII-type composed of two pairs of inclined throws can be used for low capacity and high pressure applications.

Read More

U-type compressor is suitable for services in which either two stage compression or inlet flow rates up to 50 cubic meter per minute is required.

Read More

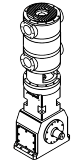

I-Type compressor with a single vertical throw is the basic design of Baron suitable for many applications such as instrument air packages and process gas services with lower pressures.

Read More

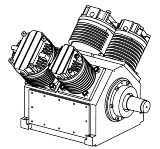

V-type compressors composed of two inclined throws can be used for compression of air or gas in 1, 2 and 3 stages.

Read More

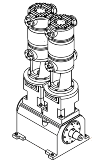

W-type compressor consists of a vertical and two inclined throws is used for creates the best balancing between reciprocating forces.

Read More

H-type compressor composed of two opposing horizontal throws is the most widely used reciprocating compressor arrangement in the oil and gas industry.

Read More

IIIH-type compressor with three pairs of opposing throws is capable of pressurizing tremendous amounts of process gas.

Read More

IIH-type compressor with two pairs of opposing throws is used for heavy duty applications in petroleum refineries and gas processing plants.

Read More