Compressor coolers

Water-cooled aftercoolers use water to cool the compressed air. They are often more efficient than air-cooled aftercoolers and are suitable for applications where water is readily available.

Intercoolers:

Intercoolers are used in multi-stage compressors to cool the air between compression stages. Cooling the air between stages improves overall compressor efficiency.

Oil Coolers:

In oil-injected compressors, where oil is used for lubrication and sealing, oil coolers are employed to dissipate heat from the compressed air and lubricating oil. This prevents the oil from overheating and ensures proper lubrication.

Combination Coolers:

Some compressors incorporate combination coolers that integrate different cooling functions into a single unit. For example, a combination cooler might include an aftercooler, an oil cooler, and a moisture separator.

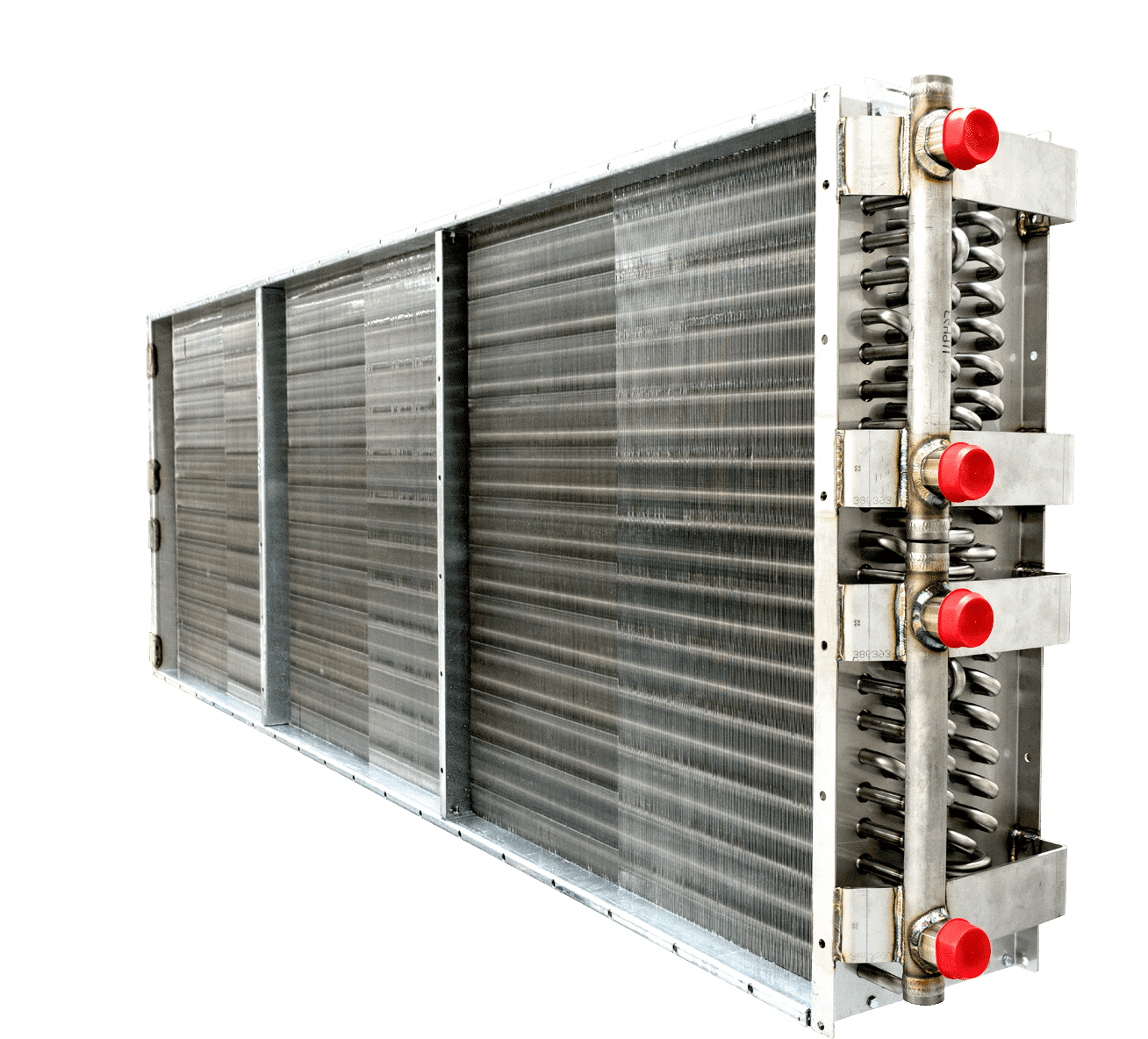

Tube and Shell Heat Exchangers:

Heat exchangers, such as tube and shell heat exchangers, are used to transfer heat between two fluids, such as compressed air and cooling water. They are effective in maintaining the desired temperature levels.

Plate Heat Exchangers:

Plate heat exchangers consist of multiple thin plates with channels for the flow of fluids. They are compact and efficient for heat transfer between compressed air and a cooling medium.

Cooling Towers:

In large industrial applications, cooling towers may be used to dissipate heat from the cooling water used in the compressor cooling system. Cooling towers use the evaporation of water to cool the circulating water.

Proper cooling is essential for maintaining the efficiency and reliability of compressors. It helps prevent excessive temperatures that can lead to mechanical failures, reduce the moisture content in the compressed air, and ensure optimal performance. The choice of cooler depends on factors such as the type of compressor, the operating environment, and the specific requirements of the application. Regular maintenance and monitoring of cooler performance are critical for the overall health of the compressor system.

Last posts

compressor single or double

A compressor can be either single-acting or double-acting, referring to the number of times the piston generates compressed air during each revolution.

Compressor piping/tubing/painting

Compressor piping, tubing, and painting are essential aspects of the installation, operation, and maintenance of a compressor system. Proper design and installation of piping, tubing, and protective coatings contribute to the efficiency, safety, and longevity of the compressor system. Here are some considerations for each:

Most viewed posts

The Russian delegation came to Isfahan

Sibur delegation visited Barun Energy and Technology Development Group

compressor single or double

A compressor can be either single-acting or double-acting, referring to the number of times the piston generates compressed air during each revolution.

Compressor piping/tubing/painting

Compressor piping, tubing, and painting are essential aspects of the installation, operation, and maintenance of a compressor system. Proper design and installation of piping, tubing, and protective coatings contribute to the efficiency, safety, and longevity of the compressor system. Here are some considerations for each: